Silver Polishing Tips:

There are a number of different commercial products available for cleaning silver: cloth, liquid, cream, paste, and foam are common products that are easily available. Do not use non-specific, all-purpose metal polishes because these contain harsher abrasives and may cause damage to the silver finish.

Commercial products that are formulated for home use are the safest method for frequent cleaning of silver. As with any method, cleaning and polishing agents contain abrasives. Be sure to close the containers tightly after use because the cleaner can dry out, making the polish more abrasive. Over time the cleaning process does remove some silver along with the tarnish and leave fine scratches on the surface. It is advisable to use the least invasive cleaning agent necessary, so that you remove only the layer of tarnish from the piece. Most commercial silver polishes contain a tarnish inhibitor. While this slows the tarnishing rate for a short time, when objects do start to tarnish they do so unevenly.

Many museums and conservators make their own polishing paste using precipitated chalk (calcium carbonate) and distilled water. Sometimes referred to as “whiting”, calcium carbonate is a superfine ground white powder that mixes easily with distilled water, and is available at most chemical supply companies and hardware stores. When using this method, it is important to have a light hand when polishing. Calcium carbonate acts as an abrasive in the cleaning process. Care has to be taken to mix a thin paste with enough abrasion to remove the tarnish without leaving scratches in the surface.

Liquid dip is a chemical mixture that, in theory, attacks the tarnish and not the silver. A dip may not be the best answer for cleaning heavily engraved surfaces because it can remove the darker in-fill on the engraved texture, leaving the silver looking flat. It is recommended that rather than submerging the object in the liquid, the dip be applied briefly to the item with a cotton-tipped applicator. Rinse in distilled water to remove any excess dip and then dry. Prolonged use of dips is not advisable, as this can lead to surface pitting. Also, chemical dips should not be used on silver pieces that have hollow sections (candlesticks or teapots with hollow handles) because once liquid leaks into a cavity, it is virtually impossible to wash it out. Remember, too, that dips are composed of an acid that is corrosive and can damage bronze, stainless steel knife blades, and organic materials such as wood and ivory. When using dips, it is important to work in a well-ventilated area and to wear rubber gloves. If, after cleaning, there is a slight yellowish cast to the silver, rub the object gently with a silver polishing cloth.

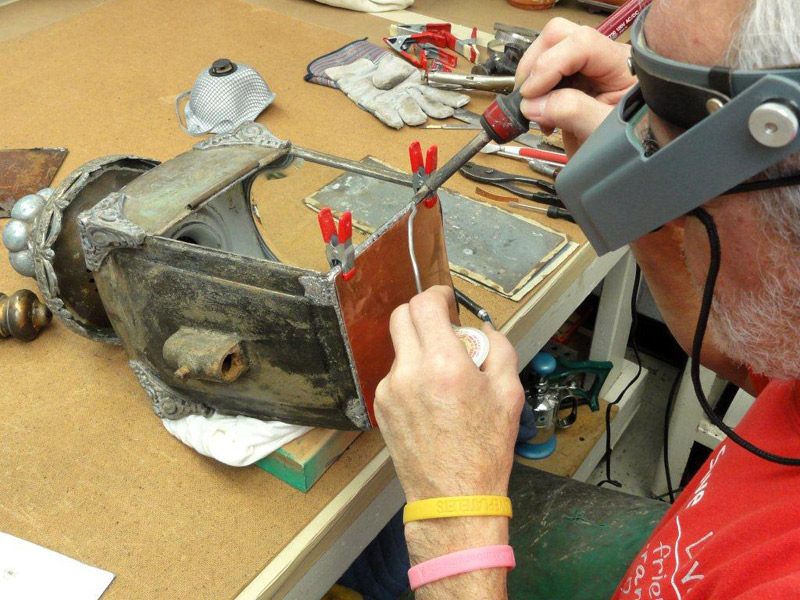

Silver that is used will eventually end up with some scratches and dents. It is generally a good idea to simply accept this cosmetic damage as a sign of character and use. If a major dent occurs on a piece that is frequently polished, prolonged handling will thin the metal and make repairs more difficult. If this happens, consult a conservator.